OUR STORY

Colorado Extraction Systems is a Wheat Ridge, CO based company. Veteran owned and operated by Colorado natives who were childhood best friends. CES has built a family of customers who come to us for our honesty, consistency and reliability. All of our systems are FDA compliant (GRAS), ergonomically designed for ease of operation, and PROUDLY BUILT IN THE USA.

OUR MISSION

Colorado Extraction Systems believes that the most effective equipment/processes should have minimal complexity and easy-to-use. We have taken the time to design and build the best systems to maximize efficiency and reduce cost. We work with the best people to deliver exceptional customer service, high performance systems with consistent output, using only the highest quality components. While we strive for working with locally owned and operated companies, all our equipment is made in the USA with globally sourced components. Smart design and superior customer relationships result in unparalleled satisfaction every time.

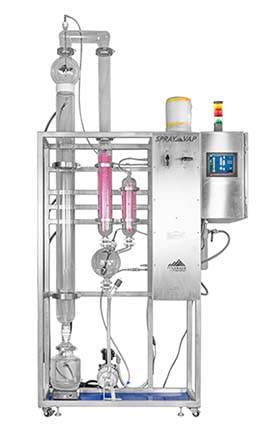

CES20

CES20