MaxXtract

MaxXtract

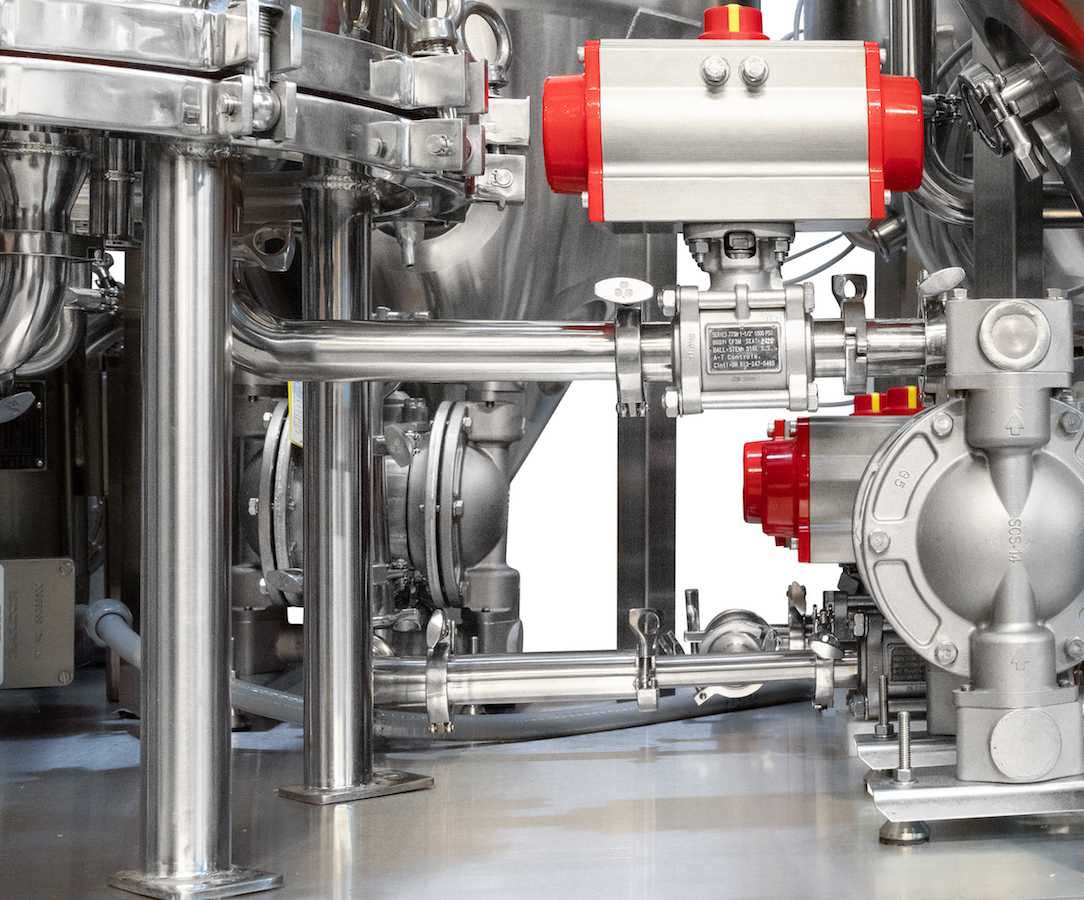

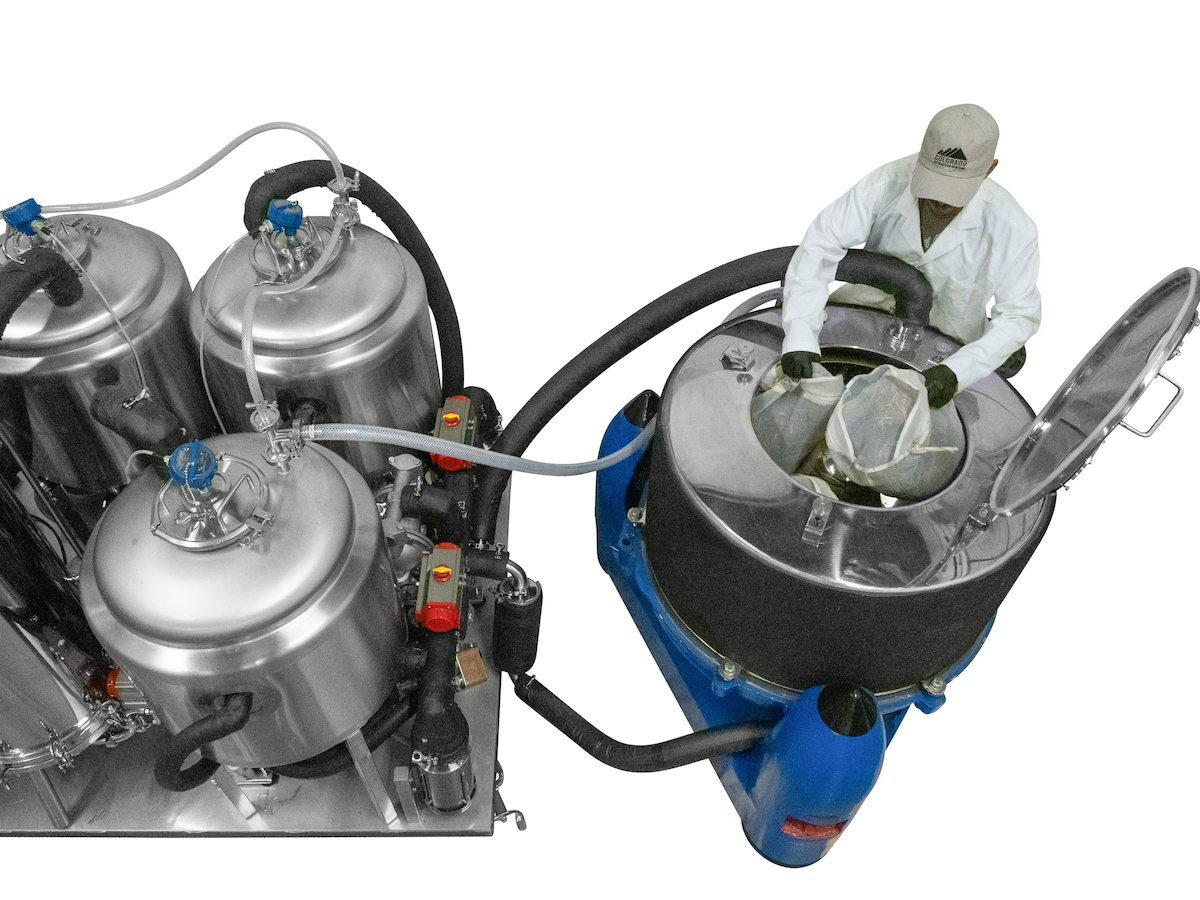

The MaxXtract® System is up to a 1000 pounds per hour fully automated, closed loop, chilled alcohol extraction system, designed for maximum extraction of cannabis plant essentials with the least amount of plant damage. Our solvent extraction system utilizes multi-tank design with centrifuge technology to drive 99+% solvent recovery while maintaining a low solvent to plant matter ratio. Dwell time and temperature are controlled to create tincture, and ultimately oil, with select cannabis plant essential properties using cold ethanol extraction.

+-Features

- Chilled Alcohol Extraction (-20C to -35C)

- Closed Loop, Fully Automated

- UL C1D2 Electronics

- UL Listed Controls with Touchscreen

- UL Explosion Proof Stainless Centrifugal Circulation Pumps

- Digital HMI Interface

- Auto/Manual Control

- Automated Level and Transfer

- 3rd Party Engineering Review (in Process)

- Liquid/Vapor Tight Double Jacketed Tanks with EPDM Seals

- Wetted Materials are Stainless Steel and Polypropylene

- All Tanks Vent to Single Point

- Seals are Viton, EPDM, or Teflon

- Max. Low Temperature -40C

- High Solvent Recovery

- Cold Ethanol Extraction Equipment

- High Extraction Efficiency

- Consistent Tincture

- Reduced Floor Space Requirements

- FDA Compliant (Gras)

- Minimal Plant Damage

- Patent Pending

- Proudly Built in the USA

- Veteran owned and operated

+-Benefits

- Easy to Use and Clean

- Rate: 30-1000 lbs per hour

- Max: 1000 lbs per hour

- Proof: 190+

- Recovery: 99%+ depending on material

+-Process Overview

- Is a closed-loop, fully automated, chilled alcohol extraction system that utilizes multi-tanks and centrifugal technology for maximum extraction efficiency. Biomass is placed inside the centrifuge. With lid secured cycle start button is pressed and biomass is processed inside the centrifuge. Once cycle is complete, light is lit, and biomass is removed and replaced with new bags. Cycle is repeated.

+-Included

- 1-year Warranty

- Installation and training

- Technical Support

- Cold ethanol extraction equipment for cannabis