SprayVap

SprayVap

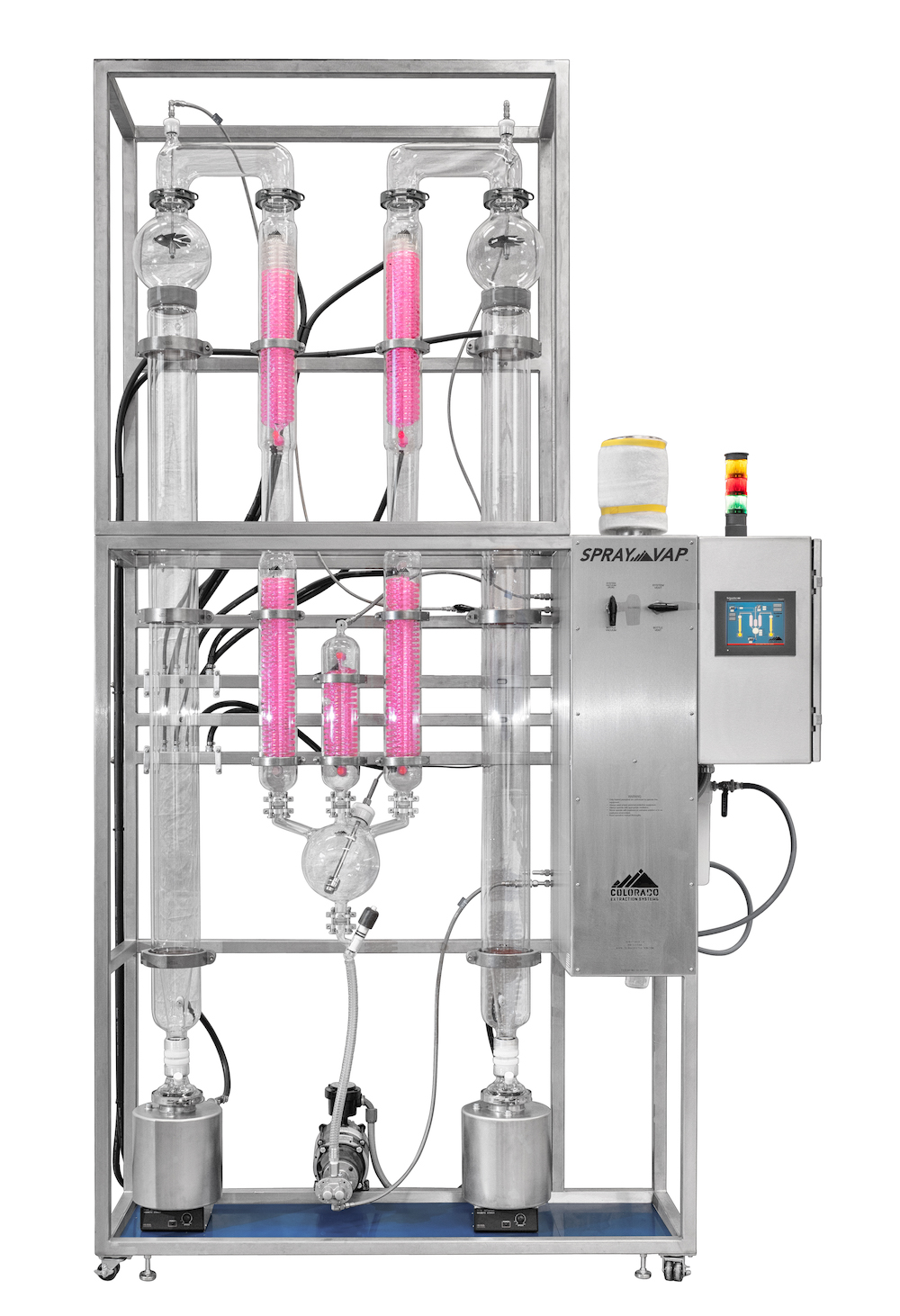

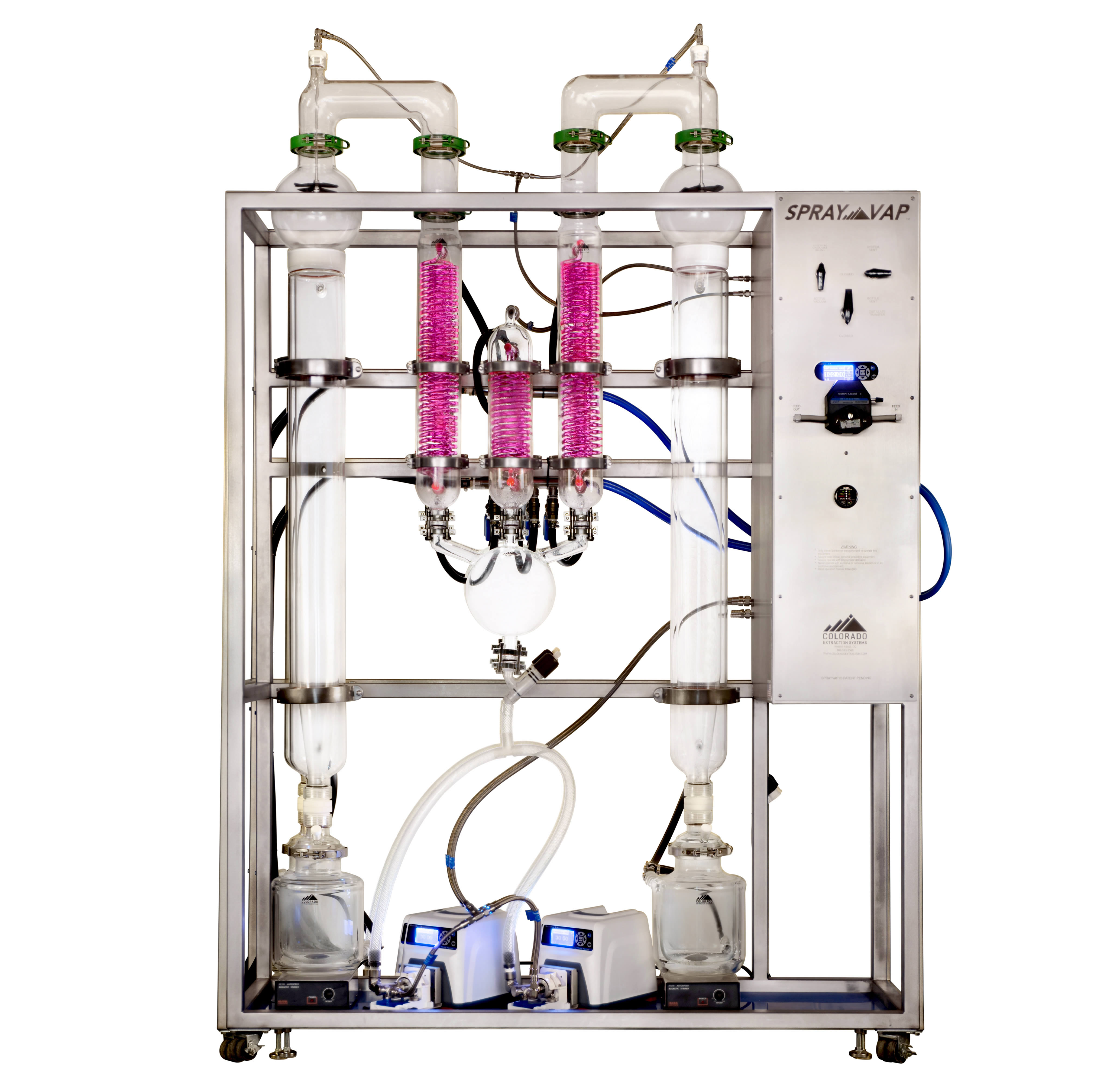

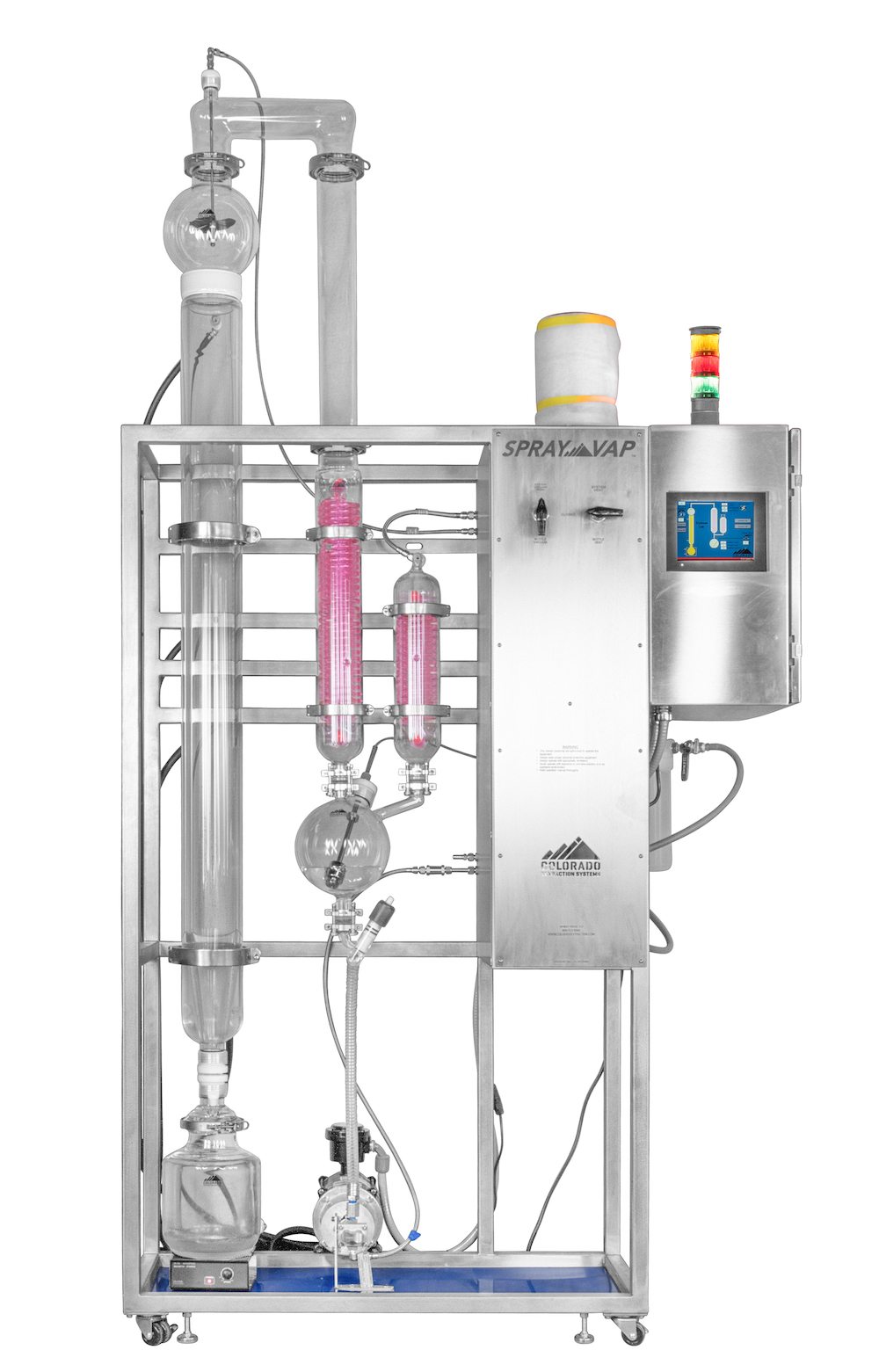

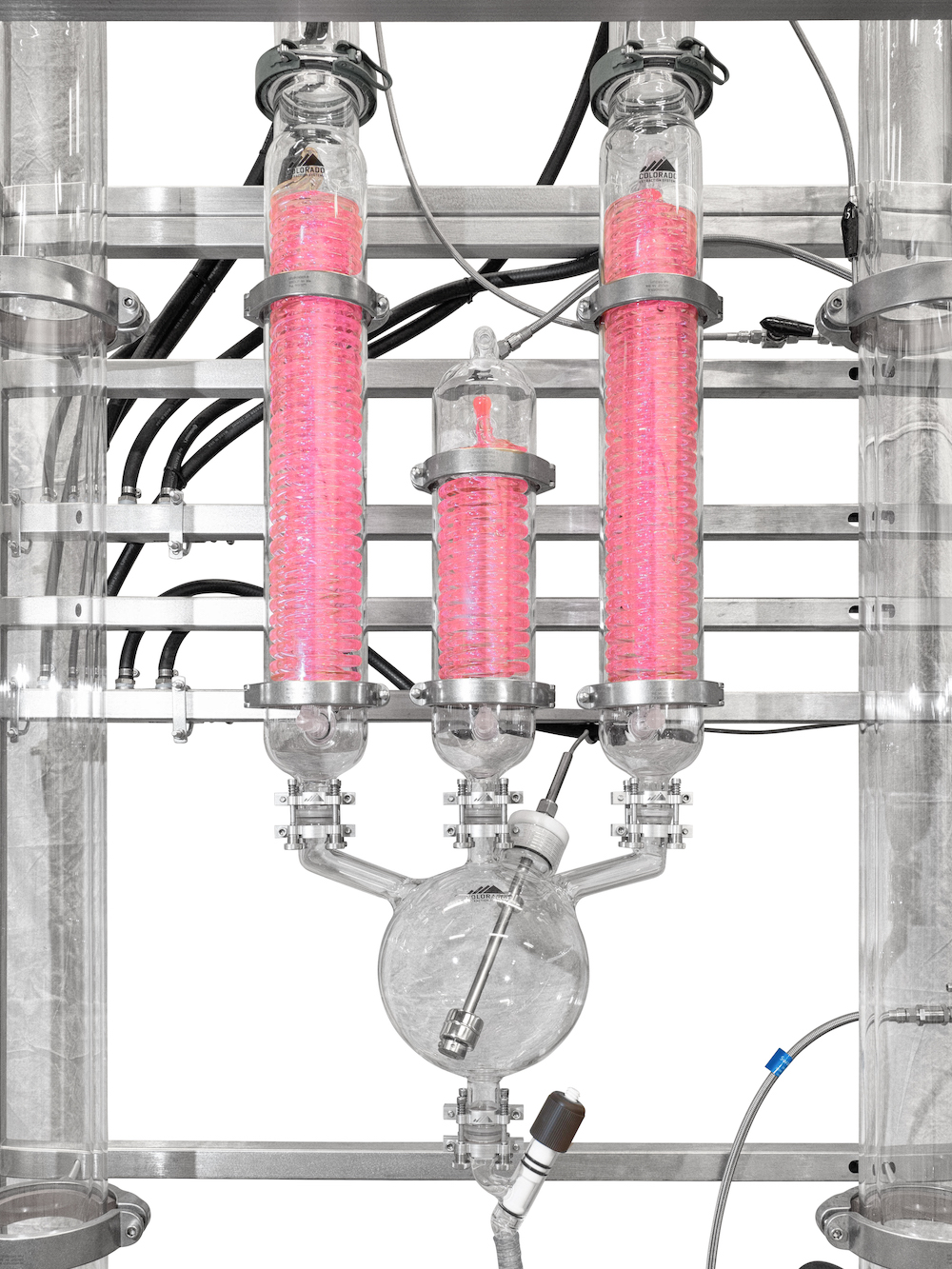

The SprayVap® is a continuous, closed loop liquid-liquid phase separation system designed for those who seek to produce high quality oil in a high throughput system with minimal maintenance and labor. Utilizing falling film technology in a safe, non-pressurized, reliable, easy-to-use design, the SprayVap® quickly and efficiently separates tinctures into two distinct streams, concentrated oil and purified distillate.

When closed looped with the TripleXtract® system, SprayVap® can convert 20 - 1000 pounds per hour to oil. Low temperatures and short residence time help preserve all the cannabis essentials for the highest quality oil.

+-Features

- Closed-Loop, Continuous Feed

- High Throughput

- Up to 99% Ethanol Recovery Rate

- Low-Residual Solvent in High Purity Crude Oil

- 3rd Party Engineering Review on most systems

- Wetted Materials are FDA compliant (GRAS) Borosilicate Glass, Polypropylene, and 316L Stainless Steel

- Chemically compatible seals (Viton, EPDM, or Teflon)

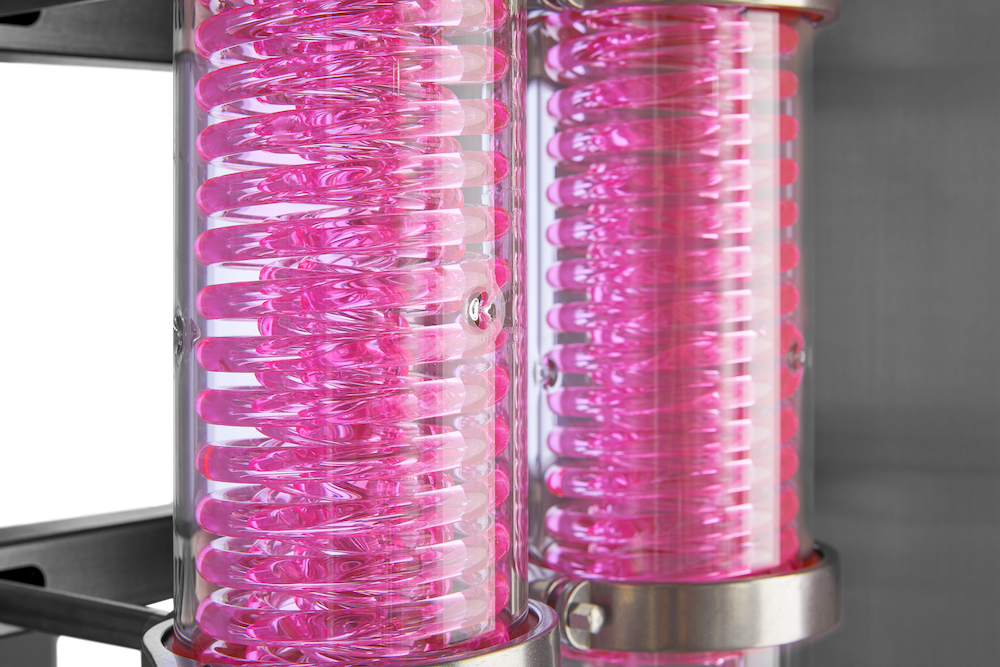

- Visual Confirmation of System Health and Operation

- Short Residence Time in Heating Zone

- Reduced Floor Space

- High Heat Transfer Coefficients due to Partial Two-Phase Flow

- Ability to Handle Foamy Liquids

- Self-Cleaning

- Low Power Requirements

- Minimal Power Requirements

- Minimal Moving Components

- Low On-Condition Maintenance

- Modular Design & Construction

- High Reliability

- Patent #10,307,689

- Proudly Designed and Built in the USA, with Globally Sourced Components

+-Options

- UL C1D2 Electronics

- UL Listed Controls with Touchscreen

- Digital HMI Interface

- Distillate Level Control System - Continuous

- Oil Level Control System - Continuous

- Oil Temperature Control

- Automated Level and Transfer

- Custom Seal Material

+-Benefits

- Consistency in the Quality of the Oil and Ethanol

- Visual confirmation of system health and operation

- Short residence time in heating zone

- Reduced floor space requirements

- High heat transfer coefficients due to partial two-phase flow

- Ability to handle foamy liquids

- Able to separate a multitude of different solvents

+-Process Overview

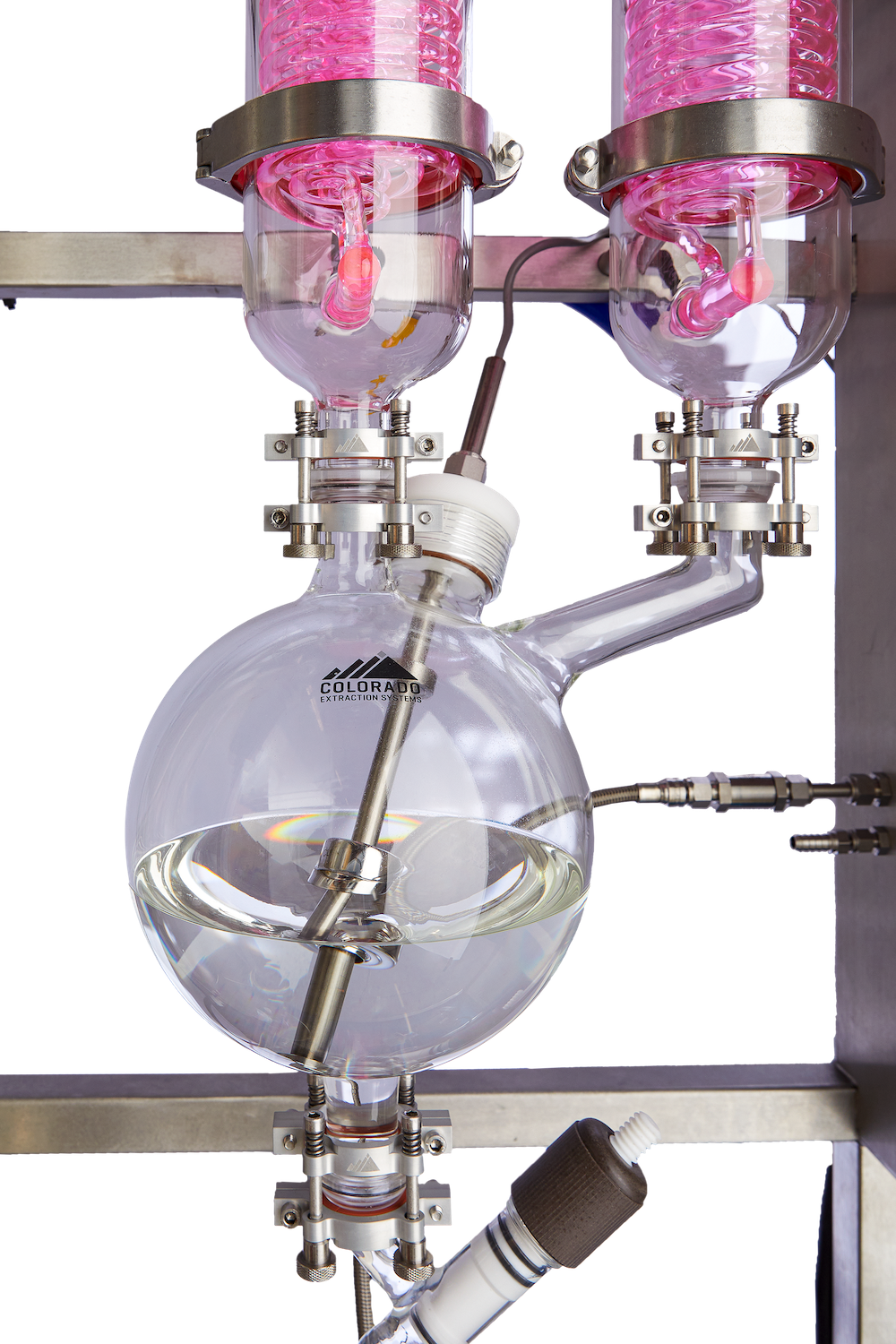

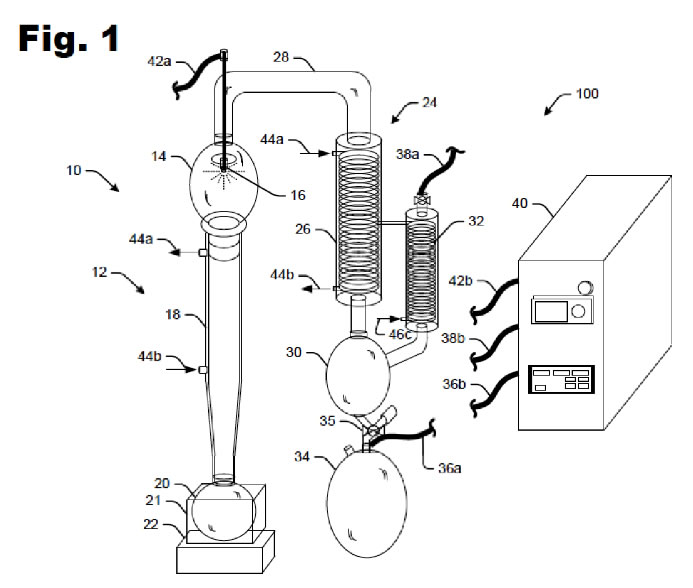

SprayVap® is a closed-loop, continuous, patent pending falling film alcohol evaporation system that separates liquids from other liquids and solids based on vapor pressures and concentrates the non-volatilized liquids and solids into an oil concentrate, while reproofing the alcohol. A tincture is fed into the system by way of a peristaltic pump (40). A vacuum system (40) is used to maintain a vacuum in the system. Vacuum is pulled through either 36a or 38a. A recirculating hot water system maintains temperature in both the evaporator column (12) thru 44a and 44b and oil collection flask (21). The recirculating chiller maintains temperature in the main condenser (26) and secondary condenser (32) between -5C and 20C. The tincture is metered into the system and flows through the spray nozzle (16), which sets up the falling film in the evap sphere (14). The falling film moves into the evaporator column (18) and releases 99.9+% of the ethanol. The vapor moves upward through (28) and is condensed in (26), however,

we have the secondary condenser (32) to condenser vapor that made it through the main condenser (26). The distillate flows through the auxiliary distillate flask (30) into the main distillate collection vessel (34). The concentrated oil is collected (20) and mixed by magnetic

stirrer (22) until collection occurs.

+-Included

- 1-year Warranty

- Technical Support

- Chiller

- Heater

- Closed Loop Extractor Equipment for Cannabis